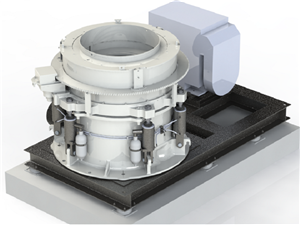

Annular Cooler

Brand SINOMALY

Product origin Liyang, Jiangsu, China

Delivery time 7 months

Supply capacity 10-800tph

1. Annular cooler as the main equipment of metallurgical pellet production process, is a very common use of cooling equipment, widely used in the cooling of pellets.

2. Diversified sealing forms include water sealing, sand sealing, heat-resistant rubber and labyrinth sealing, it provides reliable effect, more conducive to energy saving, emission reduction and waste heat recovery and utilization.

3. Equipped with leveling device, leveling materials, promoting distributing material evenly, ensuring that the air blowing without short circuit, improving cooling efficiency.

Annular cooler:

As the main equipment of pellet production process, annular cooler is a very common cooling equipment, which is widely used in the cooling of pellets. There are two main functions: blow cooling of high-temperature oxidized pellets discharged from rotary kiln after roasting to reduce its temperature to facilitate subsequent processing; As an important part of the heat balance of the whole process system, the heat in the high-temperature pellets is recovered and used for pre-heating treatment, thus reducing the fuel consumption of the whole system.

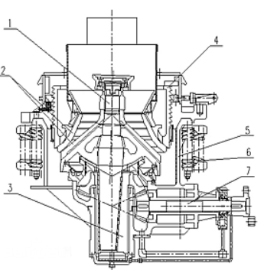

The annular cooler is mainly composed of driving device, rotating part, supporting roller, side retaining roller, pressure rail, frame, bellows, cover and so on. Transmission device for double transmission device, design to ensure that both sides of the equipment synchronous operation; The auxiliary drive device is provided to make the ring cooler run at low speed to protect the equipment in case of equipment failure; The rotating body part is the core of the whole equipment, by which the rotating operation of the material from the feed port to the discharge port and empty.

Working Principle of Annular Cooler:

The annular cooler is driven by the main motor through the main reducer to drive the sprocket to engage the annular large chain, and the large chain installed on the rotating frame drives the whole rotating body to move in a horizontal circle on the supporting roller table. After the high temperature pellets come out of the rotary kiln, they enter the feed hopper through the fixed screen and are continuously and uniformly distributed on the trolley of the rotary body, and pass through each cooling section in turn with the trolley.

Blower will bellows under the cold air into the car at the same time, the cold air in positive pressure, under the action of heat into pellets by trolley bottom clearance material layer and the heat exchange, after the hot air cooler by material layer on the surface of the top ring cover by the heat pipe to rotary kiln and chain grate discharge machine or chimney, high temperature pellets by heat exchange has cooled.

Trolley running as of rotors on stage to unloading zone, high temperature pellets to set temperature and at the same time, the rocker arm round started to grow along the curved rail trolley, trolley bottom in the pallet itself and material rotate axis under the action of gravity and slow tilt, will have the cooling of the pellets discharge to discharge groove, the material after unloading groove to the leather belt transport planes.

After unloading, the trolley begins to reset with the help of the reset roller, and its rocker wheel also descends along the curved rail, so as to force the trolley to reverse rotation until returning to its position. The annular cooler completes the whole process of high temperature pellet cooling.

Annular Cooler Specification List:

Effective cooling area | 35 | 50 | 69 | 90 | 121 | 150 | 248 |

Capacity | 78 | 125 | 152 | 190 | 270~304 | 310~385 | 630~700 |

Intermediate diameter | φ12.5 | φ12.5 | φ12.5 | φ15 | φ18.5 | φ22 | φ25 |

Trolley width | 1320 | 1800 | 2200 | 2400 | 2500 | 2500 | 3750 |

Quantity of trolley | 28 | 28 | 28 | 28 | 45 | 45 | 40 |

Thickness of material layer | 760 | 760 | 760 | 760 | 760 | 800 | 850 |

Installed Power | 2×11kW | 2×11kW | 2×11kW | 2×11kW | 2×15kW | 2×15kW | 2×22kW |

Features of Annular Cooler:

(1) Diversified sealing forms, water seal, sand seal, heat-resistant rubber, labyrinth seal, flexible and independent choice for users.

(2) The sealing effect is reliable, and a variety of sealing forms are used together, which is more conducive to energy saving, emission reduction and waste heat recovery and utilization.

(3) Compared with the belt cooler, the annular cooler covers less area, saves investment and has high equipment utilization rate.

(4) The driving device is arranged symmetrically to improve the operation stability of the equipment and reduce the deviation probability.

(5) Set up rotation speed detector, convenient for production adjustment and control.

(6) Equipping with leveling device, leveling materials, promoting even distribution, ensuring that the air against short circuit, improving cooling efficiency.

SINOMALY Heavy Machinery Co., Ltd.

Company Profile

SINOMALY Heavy Machinery Co., Ltd. was founded in 2007. As an outstanding manufacturer and supplier of production facilities, equipment and service solutions to the cement, mining, metallurgical, chemical, coal, environmental protection, power plant and steel plant industries, we have never stopped improving productivity, driving down costs and reducing the environmental impact of operations.

Covering an area of 530mu, the Company is equipped with 80 medium and large equipment with an annual manufacturing capacity of 69,300 tons of products (totally in weight).

The Company is integrated with the study of basic theory, development & design of equipment, manufacturing of mechanical & electrical equipment, technical consultant services, and supply of spare parts.

With the CE certificate, SINOMALY has her products exported to many countries including the USA, Russia, Brazil, Saudi Arabia, Peru, Pakistan, Nigeria and Vietnam, etc., and positive feedback has been received from the customers.