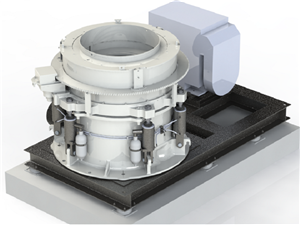

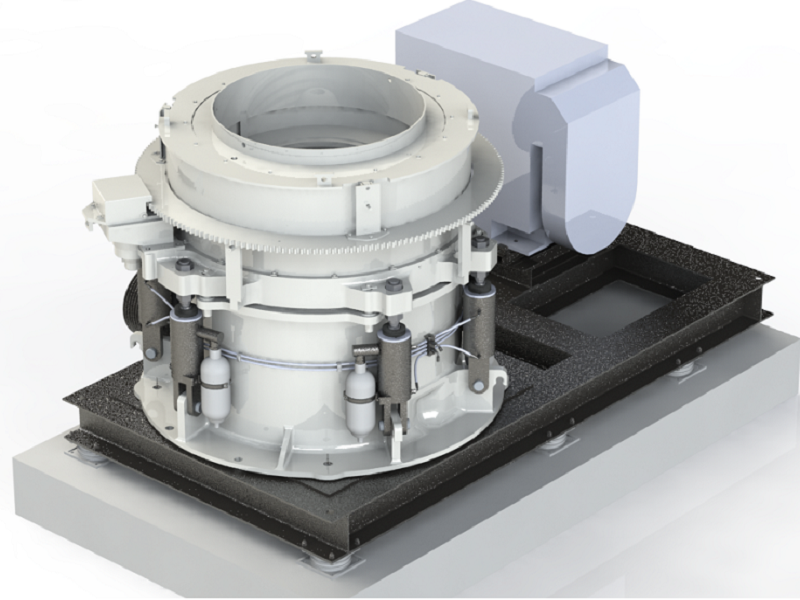

Gyratory Crusher

Brand SINOMALY

Product origin Liyang, Jiangsu, China

Delivery time 7 months

Supply capacity 10-800tph

1. Gyratory crushers are widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries.

2. The gyratory crusher is the main equipment for coarse crushing of various ores or rocks of different hardness.

3. It has the characteristics of advanced structure, stable operation, high production efficiency, convenient adjustment and low energy consumption.

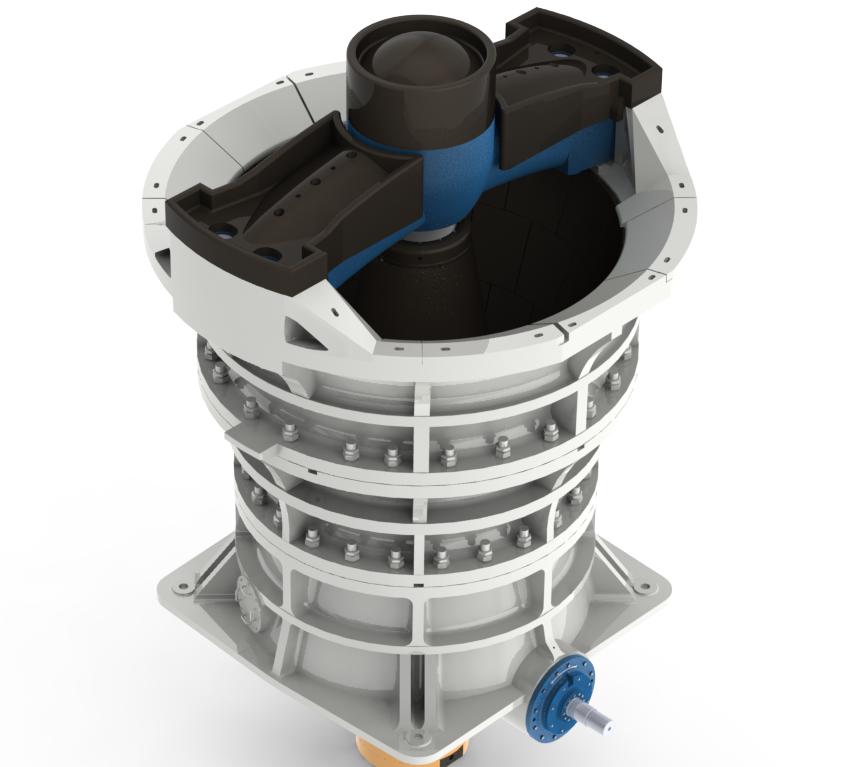

Introduction to Gyratory Crusher:

The Gyratory Crusher is widely used in mining, metallurgy, chemical, building materials, water conservancy and other industries. It is one of the main equipment for crushing coarse ore or rock. It has the characteristics of large crushing ratio, high production capacity, and uniform product particle size. The Gyratory Crusher produced by our company has complete product specifications and the maximum output can reach 5000t/h. It has the advantages of advanced structure, reliable performance, stable operation and low energy consumption.

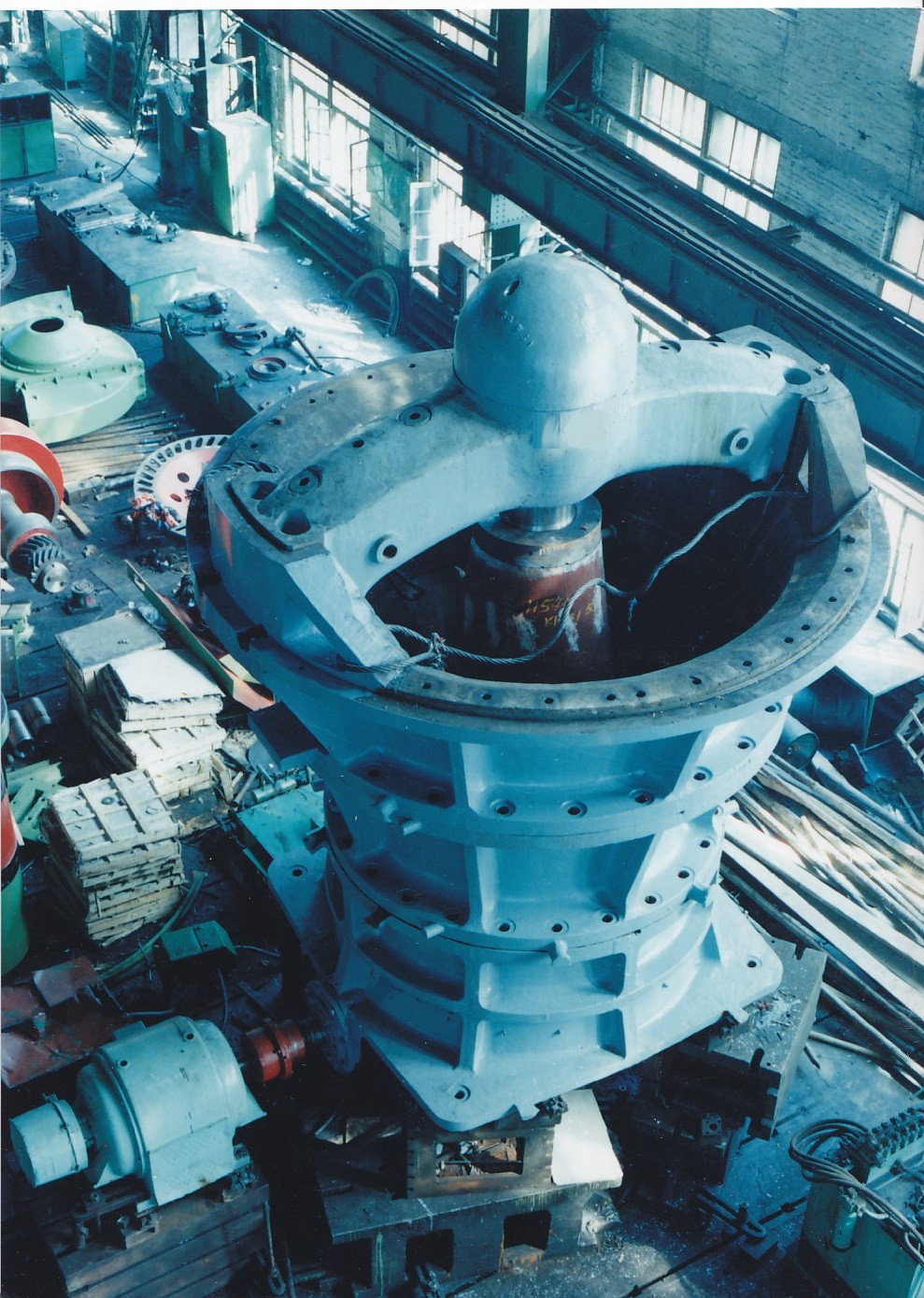

Working principle and structure of Gyratory Crusher

Working principle:

The working parts of the cone crusher are two truncated cones, one is a movable cone (inner cone), fixed on the main shaft; the other is called a fixed cone (outer cone), which is a part of the frame and is stationary. When crushing materials, due to the action of the crushing force, friction is generated on the surface of the moving cone, and its direction is opposite to the direction of movement of the moving cone, because the upper and lower parts of the main shaft are movably connected. Torque makes the moving cone rotate around the center line of the fixed axis while also rotating in the opposite direction. This rotation movement can promote a more uniform product particle size and uniform wear on the surface of the moving cone.

The working principle of the cone crusher is to apply squeezing force to the material, so that the material is crushed by the bending force and the shearing force at the same time between the two cones, and the material is freely discharged after being crushed. Its production capacity is large and power consumption is low.

The cone crusher used for coarse crushing, also known as gyratory crusher, because the machine needs to process larger lumps of material, so the feed inlet is required to be wide, the moving cone is upright, and the fixed cone is placed in an inverted direction.

For the cone crusher used for medium and fine crushing, the material to be handled is the material that has been crushed, so the feed inlet does not need to be large, but the unloading range is required to increase the production capacity, and the requirements for the crushed product are compared Uniform particle size, so the moving cone and the fixed cone are upright.

This page describes the gyratory crusher used for rough crushing.

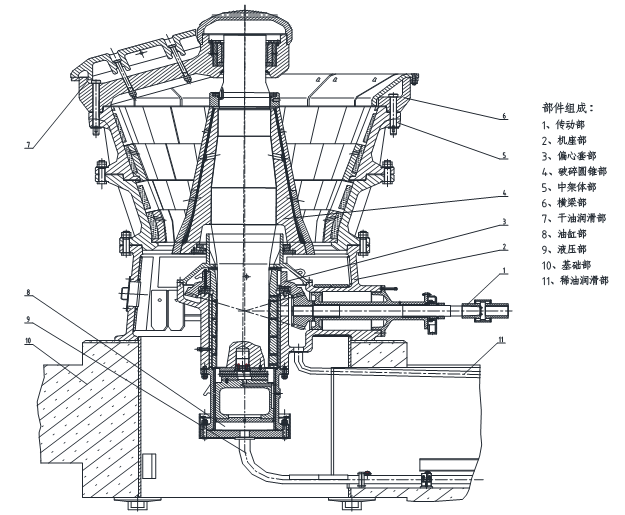

Schematic Diagram of the Structure of the Gyratory Crusher

Technical Parameters of Gyratory Crushers:

Features of Gyratory Crushers

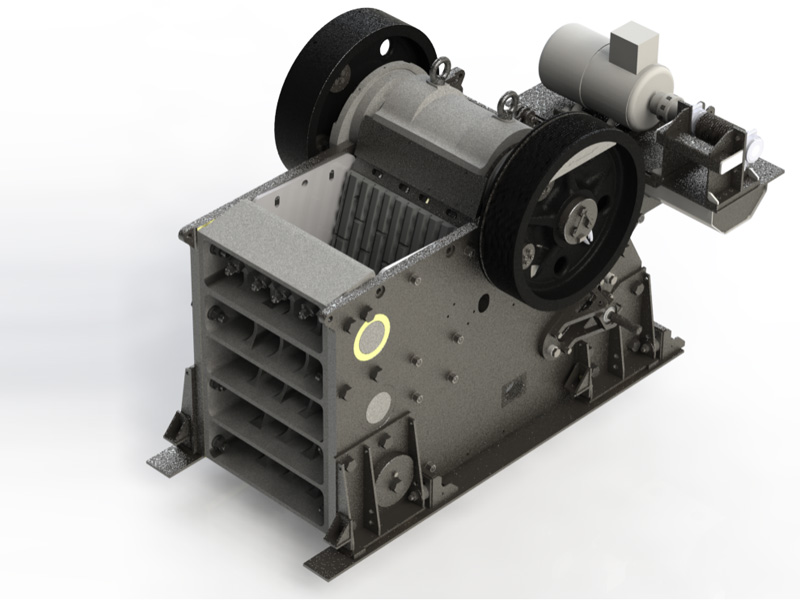

Both the gyratory crushers and the jaw crushers are crushing machines that can be used for coarse crushing. Comparing with jaw crushers, the gyratory crushers have the following advantages:

(1) The gyratory crushing process is continuously carried out along the circular crushing cavity. The

gyratory crushers feature large production capacity, low power consumption, stable operation, and uniform size of output materials. It is suitable for crushing sheet type materials.

(2) When the production capacity of the factory is large and a jaw crusher for coarse crushing cannot meet the output requirements, a gyratory crusher should be used. On the premises of the same feed size, a general gyratory crusher has its capacity twice or larger than a jaw crusher.

(3) A gyratory crusher has a deeper crushing cavity and a larger crushing ratio than that of a jaw crusher.

(4) The material to be handled can be directly fed into the feed inlet by use of a conveying unit, without need to set up a feeder. A bin can be installed on the gyratory crusher. The machine allows materials to be stacked in the bin and the crushing cavity below the bin. As the materials are crushed and discharged from the discharge outlet, the accumulated materials will gradually sink down, and new materials will continue to be fed in.

Model | Feed Port (mm) | Max. Capacity (tph) | Pinion rotary speed (rpm) | Installed power (kW) |

LZ4265 | 1066 | 5250 | 600 | 450 |

LZ5065 | 1270 | 6375 | 600 | 450 |

LZ5475 | 1370 | 7500 | 600 | 600 |

LZ6275 | 1575 | 8750 | 600 | 600 |

LZ6089 | 1525 | 12500 | 600 | 750 |

LZ60110 | 1525 | 17000 | 600 | 1500 |

Crusher production capacity | |||||||||||

Discharge port (mm) | |||||||||||

Model | t/h | 140 | 150 | 165 | 175 | 190 | 200 | 215 | 230 | 240 | 250 |

LZ4265 | t/h | 2010 | 2335 | 2515 | 2870 | ||||||

LZ5065 | t/h | 2395 | 2780 | 2935 | |||||||

LZ5475 | t/h | 2885 | 2985 | 3145 | 3335 | 3485 | |||||

LZ6275 | t/h | 2890 | 3615 | 3815 | 4205 | 4330 | |||||

LZ6089 | t/h | 4195 | 4540 | 5080 | 5530 | 5805 | |||||

LZ60110 | t/h | 5535 | 6945 | 7335 | 7570 | 8280 | 8595 | 8890 | |||

SINOMALY Heavy Machinery Co., Ltd.

Company Profile

SINOMALY Heavy Machinery Co., Ltd. was founded in 2007. As an outstanding manufacturer and supplier of production facilities, equipment and service solutions to the cement, mining, metallurgical, chemical, coal, environmental protection, power plant and steel plant industries, we have never stopped improving productivity, driving down costs and reducing the environmental impact of operations.

Covering an area of 530mu, the Company is equipped with 80 medium and large equipment with an annual manufacturing capacity of 69,300 tons of products (totally in weight).

The Company is integrated with the study of basic theory, development & design of equipment, manufacturing of mechanical & electrical equipment, technical consultant services, and supply of spare parts.

With the CE certificate, SINOMALY has her products exported to many countries including the USA, Russia, Brazil, Saudi Arabia, Peru, Pakistan, Nigeria and Vietnam, etc., and positive feedback has been received from the customers.